Arceon, an alumnus of ESA BIC Noordwijk, recently closed its funding round ahead of its ceramic matrix composites being launched into space as part of the Europe Material Ageing campaign. This milestone will enable the company to expand development of its advanced materials for extreme environments.

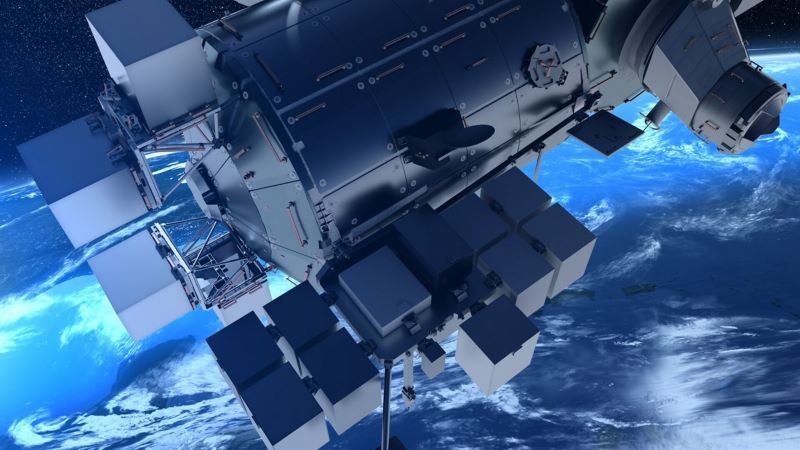

Bartolomeo payload hosting platform enables materials science research outside the International Space Station. Credit: Airbus

The team at Arceon develops extreme heat-resistant aerospace materials that are lightweight and cost-effective. Founded in 2018 by Rahul Shirke (CEO) and co-founded with Rahul Sharma (COO) and Bernhard Heidenreich (CTO), the start-up went on to participate in ESA Business Incubation programme in the Netherlands – with the support from ESA and the Netherlands Space Office – and successfully graduated from ESA BIC Noordwijk in 2023. Since then, the engineers at Arceon have been manufacturing materials for extremes in the form of composites that can withstand the harsh conditions of space.

Testing underway in low-Earth orbit

The ceramic composites created by Arceon are now undergoing rigorous testing in space. They are among a select number of materials to qualify for the Europe Material Ageing (EMA) campaign, which is collaboration between the ESA and the French Space Agency (CNES).

Ground test facilities simulating space environmental conditions enabled initial tests to be carried out at ESA ESTEC to qualify materials and spacecraft components and to better understand the degradation mechanisms. The EMA programme’s goal is to gain insight about how material ages in low-Earth orbit of the International Space Station (ISS).

Arceon’s material samples were in the payload launched as part of NASA’s SpaceX 31st Resupply Mission in early November 2024. The Bartolomeo platform, attached externally to the European Columbus Module of the ISS, is being used as a testing opportunity to perform materials science research and calibrate its ground-based testing facilities against the real space environment.

To get a better understanding about how material ages beyond Earth’s atmosphere, the materials are now set to spend a minimum of 6 months exposed to the harsh space environment. Clamped between two aluminium plates, samples with 20 mm of their exposed surface will cope with temperature extremes, radiation, vacuum and even space debris.

Ceramic matrix composites

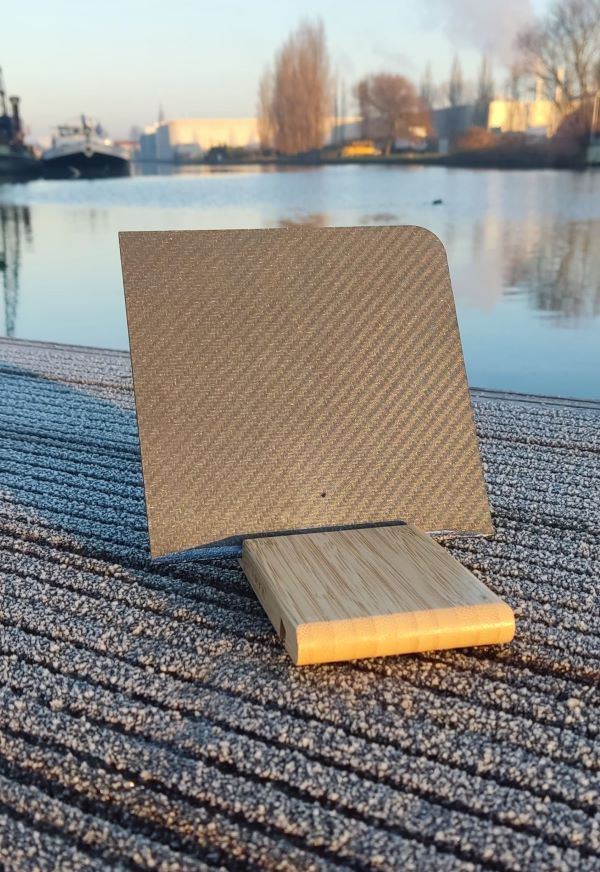

Arceon’s Carbeon material (carbon/silicon based composite). Credit: Arceon

The Arceon special composites can withstand extremely high temperatures and are lighter than the currently used alternatives, which consist of special metals.

Propulsion systems are often restricted by the thermal limitations of the metals, which leads to a lot of thrusters not reaching their full potential. Arceon’s solution enables that potential by reducing the mass – its material is four times lighter than the metals that are used currently.

The start-up doesn’t make coatings to improve materials. It makes composites for the materials. The resistance and the properties that make it efficient – that can take high thermal loads – are in the material itself.

These innovative materials consist of ceramic matrix composites (CMCs) and are a combination of ceramics and composites. The structural material – Carbeon – is based on reinforcements of carbon fibres and matrices of silicon carbide (C/C-SiC composites), which result in attractive material properties: low density, high temperature resistance, low coefficient of thermal expansion and high strength. The reinforcing fibres provide strength and stiffness, as well as damage tolerance – creating a non-brittle material. The ceramic component provides high-temperature performance and ablative resistance.

Through Arceon’s patented process, the engineers can seamlessly join the CMC components together at a late stage in the manufacturing process without any weakening of the final product. By using different fibres and additives, many of the properties can be tailored to specific applications, such as thermal protection systems and heat shields for spacecraft returning to Earth through the atmosphere.

Fuelling innovation

The results of the in-space testing are eagerly anticipated. The team sees this as a remarkable opportunity to expand awareness and further explore the capabilities and performance of Arceon’s advanced composites while presenting invaluable prospects for innovation advances on Earth. The company is in a strong position to fuel future innovation after recently receiving new investment and, as such, has closed its funding round in the Quarter 4 of 2024. Arceon will now be able to focus on expanding its commercial capabilities, market reach and operational efficiency to transform its technical success into a strong business presence. Co-founder Rahul Shirke comments: “This marks a new chapter of growth and innovation for us”.