Four ambitious European teams were selected to solve the € 100,000 technical challenge COSMIC LFAM that could turn the space economy tide. ESA will announce the phase I winning competing teams in May 2024 before proceeding with the crucial phase II.

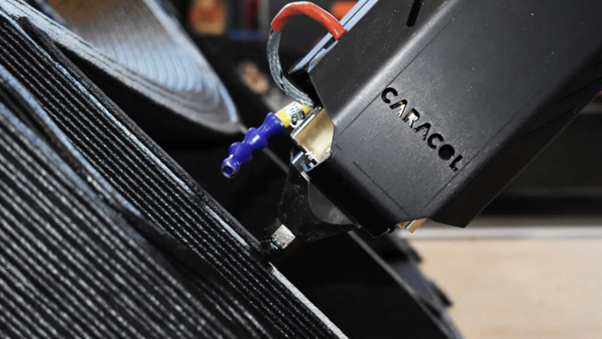

“This strategic partnership puts together a great consortium between Caracol as technology developers, a leading innovative scale up in-orbit servicing field, D-Orbit, and the European Space Agency as enabler of innovation. The aim is to support EU companies in helping them push the boundaries of additive manufacturing further, to achieve a breakthrough in the manufacturing large parts in space environments and share these learnings to lead advancements also on Earth,” says Francesco De Stefano, CEO and co-founder of Caracol.

“As a leader in the space logistics sector, we definitely support technological advances in the field of material technologies, that can ultimately lead to better products and better services for our customers,” highlighted Stefano Antonetti, VP Business Development at D-Orbit. “European SMEs and start-ups are a forge of innovative and disruptive ideas, and we are looking forward to seeing large participation in the Challenge.”

COSMIC LFAM is the opportunity to showcase the four companies’ expertise and to access ESA’s technical expertise that they may not have access to otherwise. Their innovative technology might spark the in-orbit manufacturing industry.

Maintenance is indispensable for space infrastructure, and it is more sustainable to produce spare components on-demand in space. Also, manufacturing in space requires overcoming the constraints placed on payload design.

Whilst institutional actors and long-standing space firms are the most advanced in the field of in-orbit servicing, there are a rising number of new and established companies working on technology creation for in-orbit manufacturing, in-orbit assembly, and in-orbit services. The majority of these new endeavours, however, are still in the conceptual stage.

The development of adequate manufacturing technologies requires identifying suitable materials and processing techniques for the various intended applications.

COSMIC LFAM asked the selected competing teams to devise physical model that could eventually adapt to a composite materials additive manufacturing process to be able to operate it in an uncontrolled space environment, could that be microgravity and/or reduced gravity, vacuum and temperature variations.

Or it could provide in-process monitoring capability, to be able to record the parameters of the process during the manufacturing and – or – adapt Caracol’s robotic manufacturing systems to be able to operate within the constraints of a space mission, such as volume, mass, power budgets.

The ESA Grand Challenge attracts wide communities of thinkers and problem solvers, catalysed by ESA and space, to address specific challenges with unconventional and disruptive approaches. This may also trigger development and exploitation of unforeseen spin-off businesses.

Original version of COSMIC LFAM Terms and Conditions.

New version of article “IV. Timeline” of COSMIC LFAM Terms and Conditions (with extended deadline).

Apply now