E-mobility is considered the technology of the future, not least because of its environmental and sustainability credentials. While yet another tightening of emission standards for cars and trucks is forcing the automotive industry to use the latest emissions-reducing technologies, the facts show the truth. In 2016, it was noted that almost 30% of the European Union’s total carbon dioxide emissions were generated by transports, of which the automotive sector generates more than 70%. If one considers that the number of cars produced in the world is increasing every year, it is clear at this point that the decarbonisation of transport is becoming one of the most important challenges facing civilisation. Eco-friendly “green” cars could be a solution which, if globally distributed, would significantly reduce the pollution generated by motor vehicles.

When asked whether electric vehicles are environmentally friendly, many express doubts related not to the way electric vehicles are operated per se, but to the technology used in their production. The primary focus is on the manufacturing process and testing of batteries as the power source for this type of vehicle. Manufacturers are constantly looking for solutions to make the production of batteries for electric vehicles more sustainable and efficient. Equally great attention is now being paid to recycling this type of battery in order to balance out the pollution in the production process.

The e-mobility energy ecosystem

The e-mobility energy ecosystem

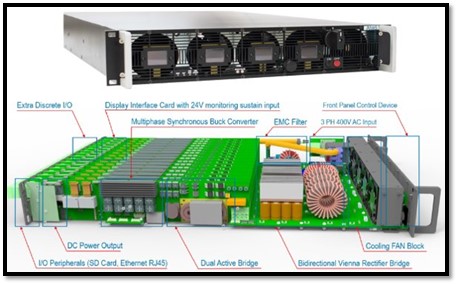

The Austrian subsidiary of the French IT service provider Atos SE – Atos IT Solutions and Services GmbH – which specialises in hi-tech transactional services, unified communications, cloud, big data and cybersecurity services, diversified its activities and engaged in the development of high-power efficiency and digital technology solutions transferred to the e-mobility domain. As the world attempts to move to a more and more green lifestyle, test solutions for battery-powered systems and battery testing must meet various market demands such as the highest power and energy density, durability, safety and energy efficiency. Atos has developed the fully digital power supply “ProUST univerSAS®”, a new unique solution of the highest efficiency, versatility and safety for testing batteries and battery-powered subsystems. ProUST univerSAS® has been designed for several markets, like aerospace, automotive and photovoltaic (PV) systems.

High efficiency Bidirectional Power Conversion technology

The strategy, with such a strong position in power testing from the space domain, is to extend it to the automotive domain, targeting battery cell R&D tester and battery cell tester. Atos delivers ground-breaking, low footprint power conversion and testing technologies that fit the operational and accuracy needs of the e-mobility industry. To meet rapidly evolving and challenging development targets, Atos is using the latest technologies such as GaN and SiC MosFET for efficient power conversion topologies. This ensures very high switching frequencies and high-speed control loop reaction times. Extremely light, compact, and unique, the Atos testing solutions can include up to 20KW and 16 independent channels inside a single device, which means each channel is isolated from each other, and each channel can be digitally controlled independently from each other. In addition, an embedded oscilloscope provides a comprehensive analog and digital information source in case of a safety event across the whole device.

“Battery testing is a topic with little awareness but increasing significance taking into account the increasing electrification of various sectors. Technology developed for space can bring a significant added value with superior quality and cost-effectiveness” says Dr. Susanne Katzler-Fuchs, CEO of Brimatech and responsible for ESA Technology Transfer Austria.

“With the shift towards battery electric and hybrid vehicles, cost and time-to-market are particularly critical for all companies in the automotive and e-Mobility industry, while every component must be tested to optimize the quality and the reliability, Atos is addressing those challenges with the latest technologies performant Power Switching Topologies from space“ says MBA, Dipl-Ing. Augusto Mattos Schaedler, Director of Atos and responsible for Product lifecycle and Innovation portfolio in Austria, Czech Republic and Romania.

As a result, this cost- and room-saving solution with powerful efficiency is unique not only in the space industry, but it can also be useful on earth, and we are just one step closer to powering electrical cars with space technologies. The carbon footprint of electric cars powered by renewable energy is 81% lower than that of their internal combustion engine counterparts. The more kilometres an electric car travels, the faster it will reduce its carbon footprint, including during the battery production phase.

ESA Technology Broker Austria is managed by Brimatech Services in collaboration with Science Park Graz under ESA Space Solutions Austria. It is funded by ESA Space Solutions and the Austrian Research Promotion Agency.